WIRE EDM

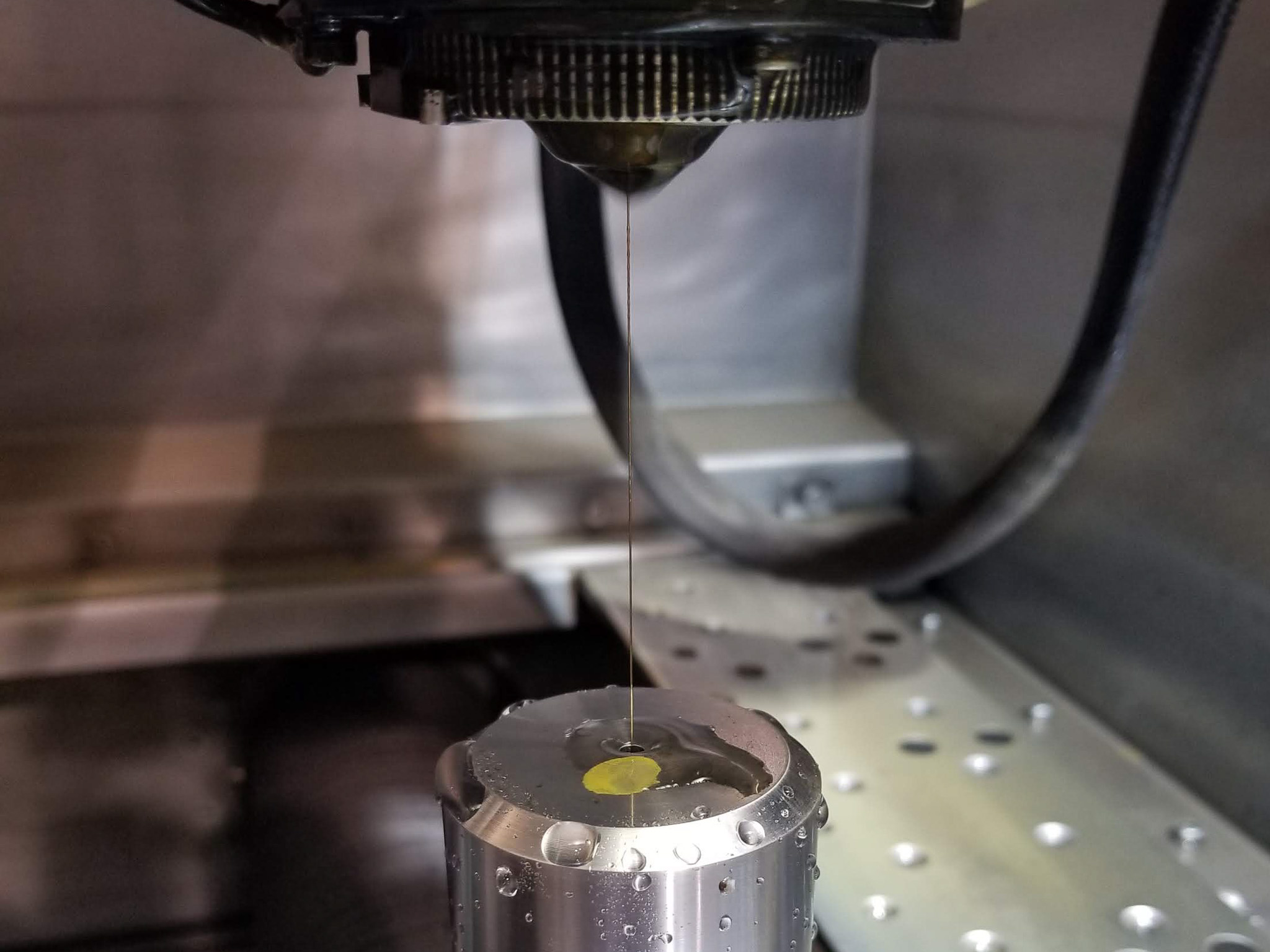

Electrical Discharge Machining is obtained by using electrical discharge. MKM has 2 wire machines, 1 hole burner, and 1 sinker. EDM process is typically used when traditional machining methods would be difficult. There is no contact with the workpiece therefore no distortion or damage from excess tool pressure.

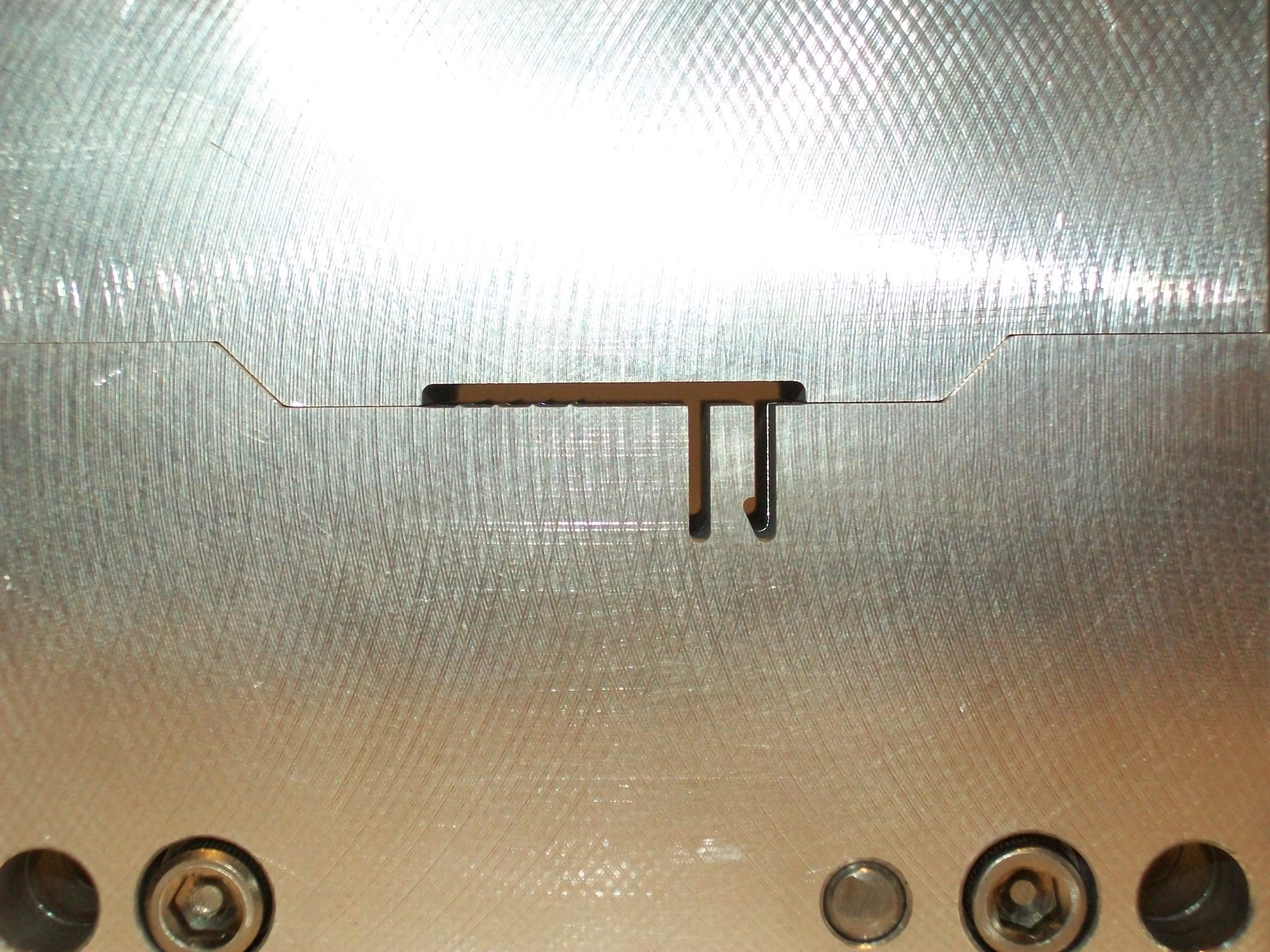

Wire EDM achieves the highest level of precision and surface finishes ideal for plastic extrusion dies, electrical, aerospace, & medical parts. In addition, wire EDM is capable of cutting the most difficult material carbide, hastelloy, and inconel.

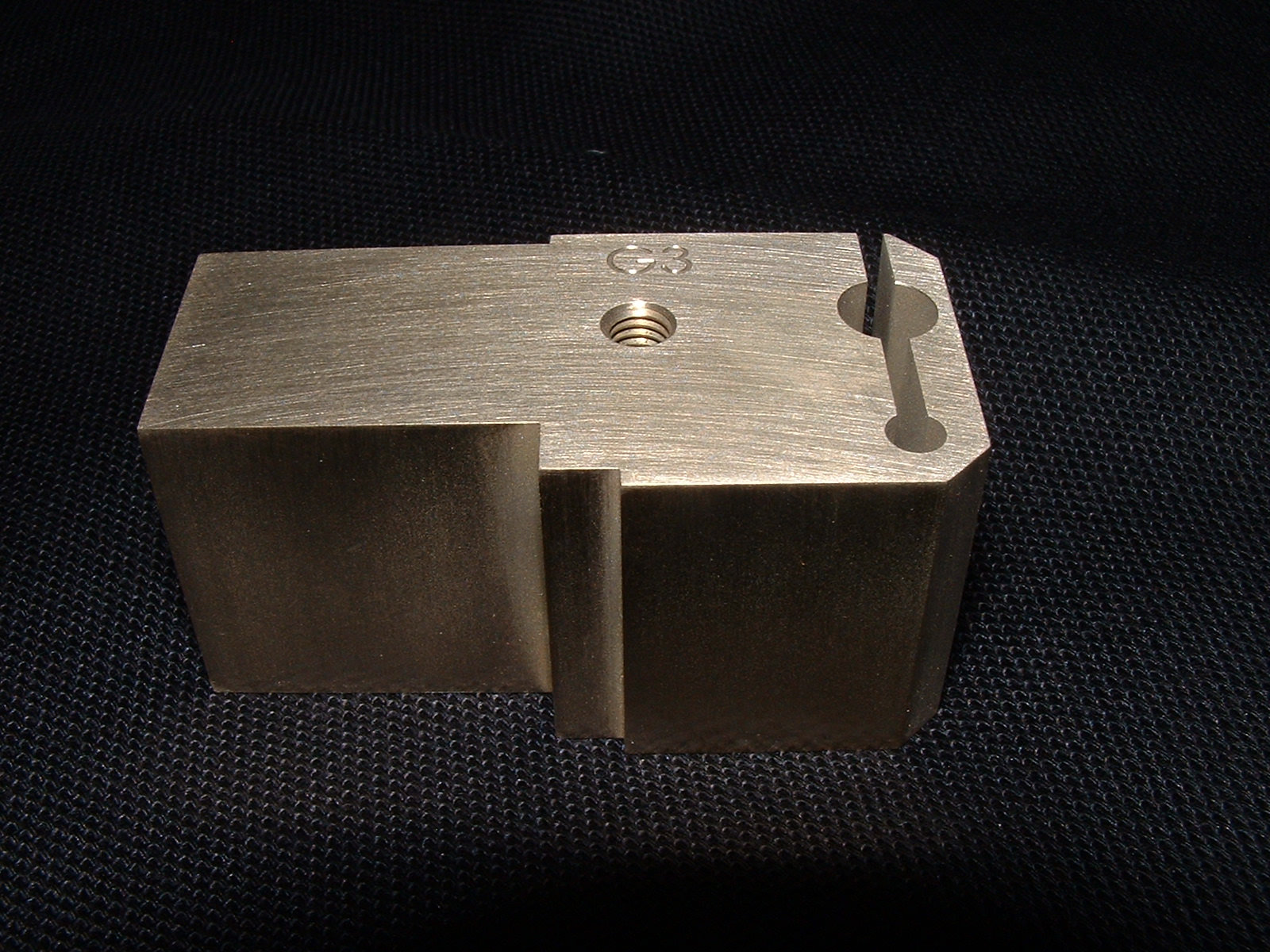

A Hole burner and sinker creates a plasma channel using an electrode. A Hole burner can create small holes down to 0.030” in size in difficult machining materials. In addition, MKM sinker can create tapered and hexagon shaped holes with great surface finishes. They can also remove broken tooling, from the workpiece while leaving the hole intact.